Study on photoelectric characteristics of liquid crystal dimming film by temperature With the increase of temperature, the switching state parallel light transmittance decreases gradually, because the selected temperature range is moderate, so the overall reduction is smaller. The open state of fog is mainly related to the properties of Ito films, and the lower the fog of open state, the clearer the display.

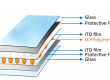

With the increase of temperature, the fog degree of the closed state increases gradually, the higher the degree of shutdown, the better the privacy effect, if the high fog dimming film applied to the projection display, will show an excellent display effect. The liquid crystal dimming film is composed of two layers of flexible transparent conductive film and a layer of polymer dispersed liquid crystal material (PDLC). The polymerization speed of polymer monomer in PDLC material and the solubility between liquid crystal and monomer are limited by temperature conditions, so temperature plays a decisive role in the control of relative separation process. When the temperature is low, the polymerization speed of the monomer is slow, the liquid crystal precipitates quickly from the monomer, so the liquid crystal is rapidly precipitated from the monomer, forming a lot of nano-sized droplets, nano-sized droplets are prone to phagocytosis, resulting in the increase in the size of the liquid crystal droplets, weakening the scattering effect of the PDLC film on light, therefore, The parallel transmittance of the closed state is relatively high, in addition, the diameter of the liquid crystal droplet increases, and the anchorage force of the polymer is relatively weakened, so the threshold voltage and saturation drive voltage of the liquid crystal dimming film are relatively low. The increase of polymerization temperature will increase the direct solubility of liquid crystal and polymer monomer, so that the speed of liquid crystal molecules from monomer precipitation decreases, inhibit the mutual phagocytosis between liquid crystal droplets, the increase of temperature will also cause the speed of monomer polymerization increases, when the speed of liquid crystal molecules precipitated from the monomer and the polymerization speed of the monomer to achieve balance, It is easy to form liquid crystal droplets, which should be evenly distributed in polymer networks, so the scattering effect of PDLC films on light is strong, and the parallel optical transmittance of the closed states is relatively high. In addition, the liquid crystal molecules at this time due to the strong anchoring force of the polymer, resulting in the PDLC membrane threshold voltage and saturation drive voltage become larger.

Therefore, in the case of consistent other process parameters, the liquid crystal dimming film coil production should choose the appropriate temperature, so that its comprehensive performance is optimal.