Electric heated glass/ electrically heated glass/Electro heated glass

The working principle of electric heated glass is that after the glass is energized, its surface temperature begins to rise, and the rising temperature range is within the range, so that the heating temperature of the glass is equal to or slightly higher than the surface temperature of the glass, so as to achieve the effect of not producing fog and frost.

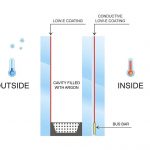

Electric heating glass uses low voltage, low power consumption, and safety. Electric heating glass is also called electric heating glass, anti-fog glass. It is mainly composed of two parts, tempered glass, transparent electroplating film embedded layer, and electroplating film embedded in the middle of the tempered glass. Tempered glass can choose flat or bent steel. When energized, the glass itself will heat up, and its own thermistor is connected to the temperature control system, and the surface temperature can be automatically adjusted.

Electric heated glass performance:

1. Excellent frost defrosting function: After the electric heated glass is energized, the surface temperature will rise (usually 35~40 ℃), so that the glass surface will not have frost and dew condensation, and the voltage is safe and does not harm the human body.

2. Excellent optical properties: The electric heated glass adopts conductive wire or conductive film as the heating medium to ensure that the glass has excellent light transmittance and anti-distortion performance, which can achieve clear and real objects through glass observation.

3. Good safety: The laminated glass of the electric heated glass is made of tempered glass. The tempered glass has high hardness and is not easy to break. Even if it encounters a gravity impact, the glass fragments will be stuck with organic mucous membranes, and will not splash around and hurt people.

4. Anti-ultraviolet radiation function: The glass has high ultraviolet absorption capacity, which can effectively block ultraviolet rays from entering the room and reduce the damage of ultraviolet rays to drivers and indoor facilities.

- electricalldy heated glass dor display carbinet

- electrical heated glass testing

- electrically heated glass dor food display

How It Works

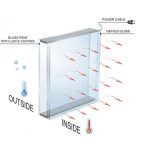

The specialist Heated Glass has a transparent metal oxide coating applied to the glass unit. Electricity is passed through the coating via buzz bars at the head and the base of the unit which are concealed within the glass construction.

The heated glass coating is a semi conductive material, when electricity is passed through the coating it generates a radiant heat source. Depending on the power input into the glass this radiant heat can either be used to heat a space using the infra-red radiation, create a warm surface to the glass to stop condensation forming on the glass, or create a warm surface on the outside of a glass structure to stop snow or ice build-up.

- Electrically heated glass structure

- transparent electric heating glass working principle