Installing smart film can be a DIY project if you’re handy, or you may prefer to hire a professional. Here are the general steps:

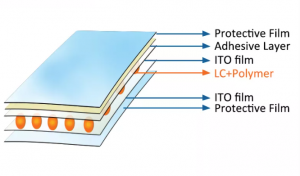

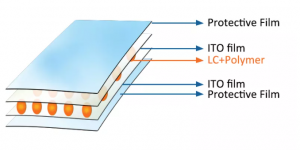

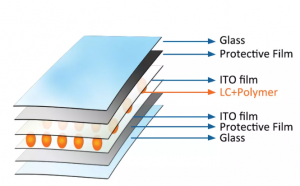

You know protection film for mobile phone, car window film, but do you know smart glass film ? The smart glass film is sandwich between two pieces of glass to make smart glass, or an adhesive Smart glass film and paste on the glass surface, both of which can realize the conversion between transparent and opaque glass.

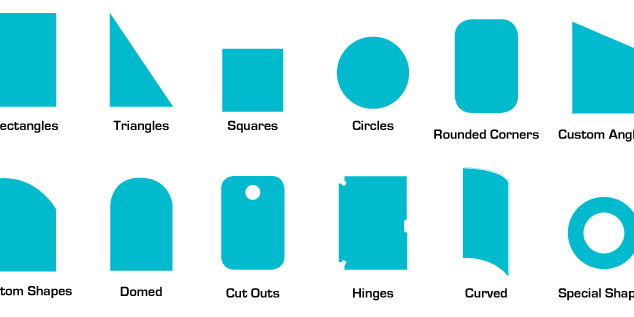

- self adhesive pdlc smart glass film

- non adhesive pdlc smart glassfilm

- PDLC smart Glass

Smart glass film is usually in the field of architectural decoration, such as hotels, office buildings, shopping malls, apartments and other large-size glass.

Some customers have many questions about how to paste and use the smart film because of their first contact with it. Below we list some precautions for you when pasting.

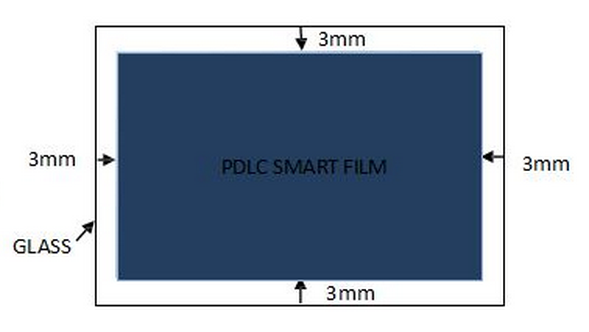

1. Determine the size

Once the size of the pdlc smart glass film come out, basically it cannot change. so it is very important to measure the size of the glass, and only in this way can the pdlc smart glass film match the glass. Basically, a piece of glass pastes with a smart glass film, but sometimes the glass is larger than the larger size of the smart film, and then multiple pieces of dimming smart glass film aneed to be spliced and pasted. If it is a combination of glass and glass, you must pay attention to subtracting the size of the glass glue in the seam and mark it when cutting the dimming smart glass film.

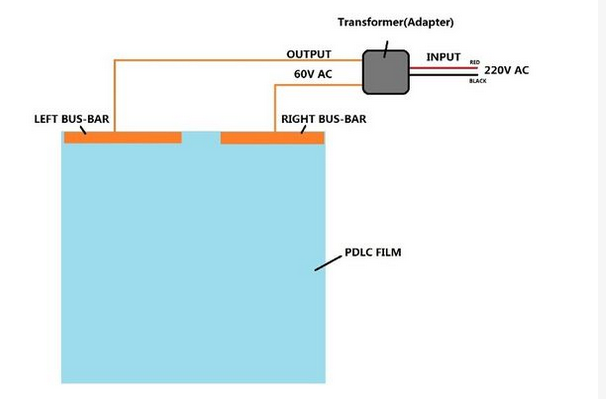

2. Determine the electrode position

It stands to reason that the electrodes of the dimming smart glass film can place on any side, but the ultra-long dimming smart glass film may require electrodes on both sides. The electrode position is better for the convenience of wire routing and connection to the power transformer.

3. Glass cleaning

Paste The dimming smart film on the clean glass smooth surface after removing the dust and impurities on the glass surface. If the glass is not clean with water, it can use alcohol.

4. The film should be pasted from top to bottom

First fix the top of the smart glass film, tear off the protective film at an angle of 45 degrees from top to bottom, then align the glass, slowly stick the film on the glass, squeeze out the air bubbles with a scraper while sticking, do not use too much force. Also be careful not to covet the convenience of water stickers. This process requires the cooperation of more than 2 people to complete.

5. Protect the edge of the dimming smart glass film

After sticking the film, use one-sided adhesive to stick the edge of the protective film, and then slowly tear off the protective film. Do not use a blade or fingernails to scratch the protective film, it is easy to cause open edges.

Measure the Glass: Carefully measure the glass surface where you plan to apply the smart film. Precision is key here – it’s better to have a bit extra that can be trimmed later than not enough.

Cut the Film: Using your measurements, cut the smart film to size. Again, it’s better to err on the side of cutting the film slightly larger than necessary.

Clean the Glass: Thoroughly clean the glass surface. Any dust or debris can prevent the film from adhering properly.

Apply the Film: Peel off the protective layer from the adhesive side of the smart film and carefully apply it to the glass. Be sure to remove any bubbles that form – a small squeegee can be useful for this.

Connect to Power: Connect the wires from the film to a transformer or switch. This will provide the electrical current needed to switch the film from opaque to transparent. Always consult a professional if you’re unsure about this step.

Test the Film: Once everything is installed, test the film to make sure it works correctly. If you notice any issues, refer to the manufacturer’s troubleshooting guide or contact them for support.

For the switchable PDLC smart glass film, after installation, should use special neutral silicon sealant to seal the edge and electrode position, mainly there have the following reasons:

1). Prevent water vapor and other liquids from eroding the polymer and liquid crystal layer in the middle layer of switchable PDLC film;

2). Avoid water vapor and other liquids from eroding the electrode position;

3). Protect the oxidation of copper strip and silver paste layer;

4). Avoid the edge of the film from separating from the glass due to air entering;

At the same time, the switchable PDLC film has the following requirements for the sealed silica gel:

(1. must use neutral silicon sealant;

(2. No shrinking for silicon sealant glue when dried;

(3. Silicon sealant without organic solvent and Plasticizer material;

We recommend Toshiba 381 or our special silicon sealant;

Other types of silicon sealant need to confirm with the supplier whether they meet the requirements and carry out use test before use;