How to make Smart PDLC Film ?

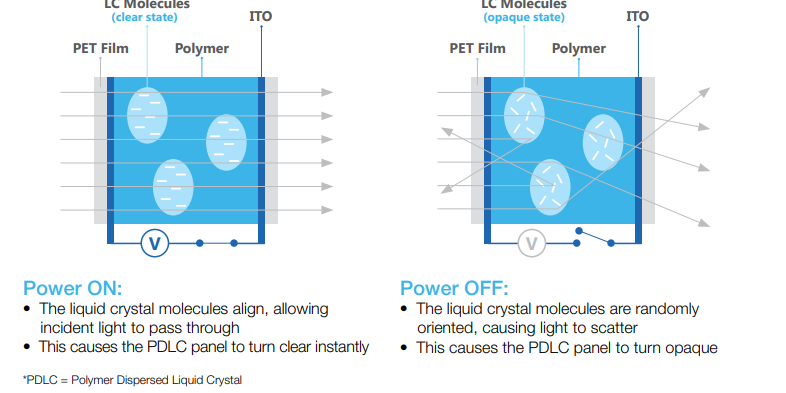

Smart PDLC film is a switchable glass technology that changes from opaque to transparent when an electric current is applied. It is widely used in smart windows, privacy partitions, and projection screens.

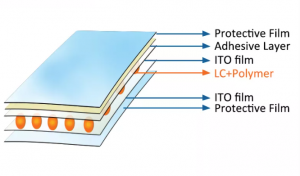

PET full name is Polyethylene Glycol Terephthalate. ITO Full name is Indium tin oxide(ITO),In2O3 • SnO2.

1. Key Components of PDLC Film

| Component | Function |

|---|---|

| Liquid Crystals (LCs) | Switch between opaque and transparent states |

| Polymer Matrix | Holds liquid crystals in place |

| Conductive Layers (ITO/PET) | Apply voltage to control transparency |

| Adhesive & Protective Layers | Ensure durability and easy installation |

Manufacturing Process of PDLC Film

Step 1: Prepare the Liquid Crystal-Polymer Mixture

Mix nematic liquid crystals (LCs) with a UV-curable polymer (e.g., PMMA, NOA65).

Typical ratio: 60-70% LCs, 30-40% polymer.

Add photoinitiators (for UV curing) and surfactants (to stabilize droplets).

Step 2: Coat the Mixture onto Conductive Substrates

Use ITO-coated PET films (Indium Tin Oxide for conductivity).

Apply the LC-polymer mixture between two ITO-PET layers using:

Roll-to-roll coating (for mass production).

Doctor blade/Spin coating (lab-scale).

Step 3: UV Curing to Form Polymer Matrix

Expose the film to UV light (300-400 nm).

The polymer hardens, trapping LC droplets in a polymer network (PDLC structure).

Step 4: Laminate & Seal the Film

Add protective layers (EVA, PET) to prevent moisture/oxygen damage.

Seal edges with hot melt adhesive or epoxy resin.

Step 5: Connect Electrodes & Test

Attach copper electrodes to the ITO layers.

Apply AC voltage (50-100V, 50-1000Hz) to test switching performance:

ON (Transparent): ~80-90% transmittance.

OFF (Opaque): ~5-20% transmittance (milky white).

Key Parameters Affecting PDLC Performance

| Parameter | Impact | Optimization Tips |

|---|---|---|

| LC/Polymer Ratio | Higher LC = better transparency, but weaker film | 60-70% LC is optimal |

| Droplet Size (1-10µm) | Smaller droplets = faster response, higher haze | Control via curing speed |

| Voltage (50-100V AC) | Higher voltage = faster switching | Avoid >120V (damages film) |

| Frequency (50-1000Hz) | Higher frequency = better stability | 500Hz is common |

Applications of Smart PDLC Film

Smart Windows (Privacy glass, energy-saving buildings)

Projection Screens (Switchable transparent displays)

Automotive & Aviation (Sunroofs, cabin partitions)

Medical & Security (X-ray privacy screens)

DIY vs. Industrial Production

| Aspect | DIY (Lab Scale) | Industrial (Mass Production) |

|---|---|---|

| Materials | Small batches, high cost | Bulk purchasing, lower cost |

| Equipment | Spin coater, UV lamp | Roll-to-roll coating machines |

| Quality | Inconsistent | High uniformity |

| Speed | Slow (hours/film) | Fast (meters/minute) |

Troubleshooting Common PDLC Film Issues

| Problem | Cause | Solution |

|---|---|---|

| Weak Transparency | Poor LC alignment | Optimize polymer curing |

| Slow Switching | Large LC droplets | Reduce droplet size (faster UV cure) |

| Electrical Failure | ITO layer damage | Use better conductive coatings |

- pdlc smart glass film working effect

- self adhesive pdlc smart glass film

- non adhesive pdlc smart glassfilm

Smart PDLC film production involves mixing LCs with polymers, coating onto conductive films, UV curing, and laminating. Key factors like LC ratio, droplet size, and voltage determine performance..