What You Need to Know Before You Start?

Personnel preparation: For non-professionals, it is recommended to have two individuals for installation. One person is responsible for lowering the film, while the other person is responsible for sliding away the bubbles. Professional personnel can handle the installation alone. For widths greater than 1.2m, it is advisable to have 2-3 individuals install together.

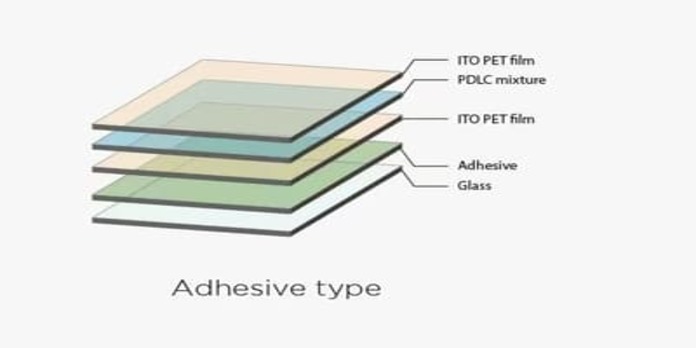

Environment preparation: Please make sure the work environment is as clean and dust-free as possible. Dust will easily lead to bubbles between the PDLC film and the glass surface. In front of the glass, you need a free space equal to the height of the glass itself to be able to move easily.

Dry installation process: Installing adhesive PDLC film is a dry process. Never use water; instead, use 99% isopropyl alcohol (industrial alcohol) to clean glass surfaces. Do not operate until the glass surface is 100% dry!

Protective layer handling: Please refrain from removing the protective layer (self-cling side) of the PDLC film until you are prepared to install the smart film. Keep the protective layer (non-cling side) intact until the installation is finished.

Avoid chemical cleaners: Avoid using any chemicals or abrasive cleaners on the smart film surface and glass surface, due to they may corrode the PDLC film. We recommend using either anhydrous alcohol or 99% Isopropyl Alcohol along with a lint-free cloth to clean the glass surface..

Careful Film handling: To prevent delamination, it’s important to handle the film edges with care. Never fold, bend, or curve smart film. Ensure that the film is kept flat and straight as demonstrated below.