Anti-condensation glass for home windows

Anti-condensation glass for home windows is designed to prevent the buildup of condensation on the glass surface, ensuring clear views and reducing the risk of mold and moisture-related issues. This type of glass is particularly beneficial in climates with high humidity or significant temperature variations between indoor and outdoor environments.

How Anti-Condensation Glass Works

Anti-condensation glass typically incorporates one or more of the following technologies:

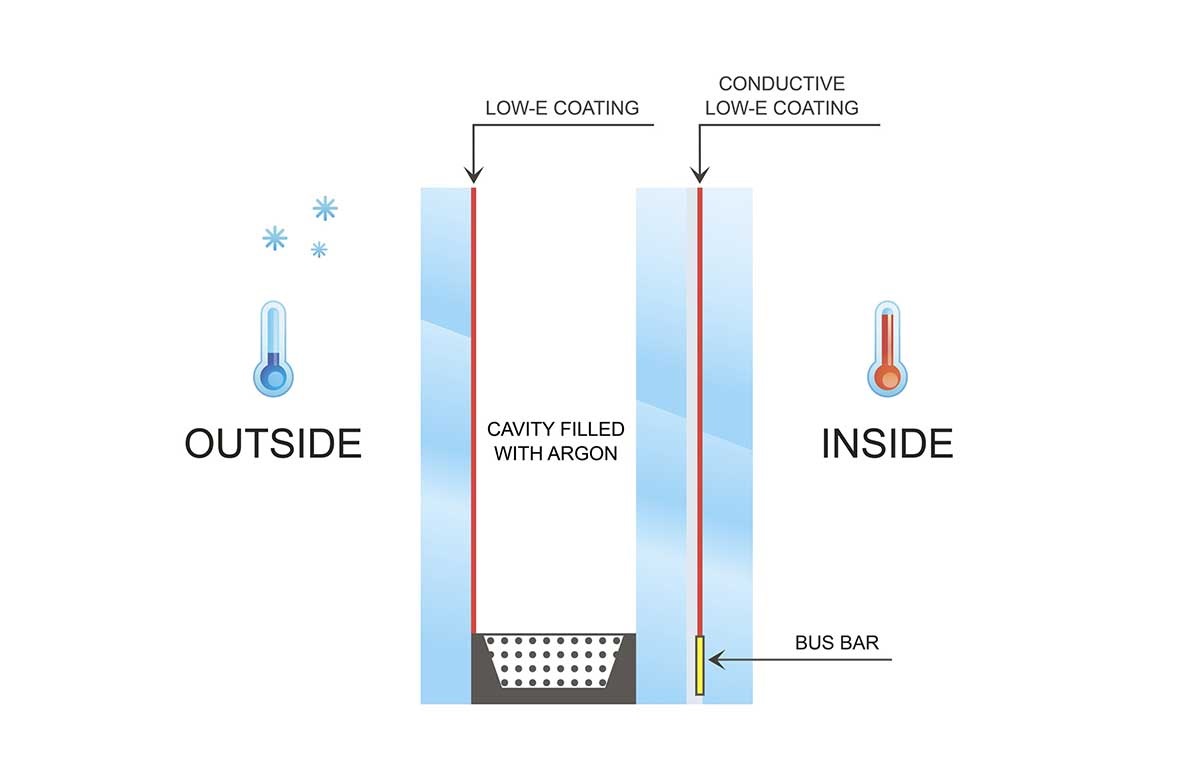

1.Low-Emissivity (Low-E) Coatings

These coatings reflect heat back into the room, keeping the inner surface of the glass warmer. This helps to reduce the temperature difference between the glass and the indoor air, thereby minimizing the potential for condensation。

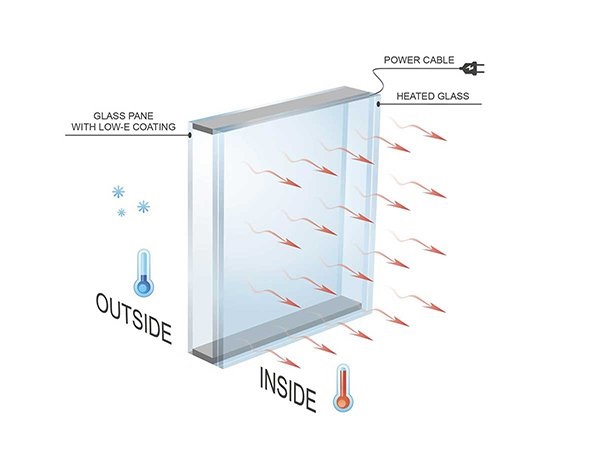

2.Electrically Heated Glass

Features a transparent conductive coating that can be electrically heated to maintain a warm surface temperature, preventing condensation from forming.

3.Insulated Glass Units (IGUs)

Consist of double or triple glazing with a sealed air or gas-filled space between the panes. This design improves thermal insulation, keeping the inner pane warmer and reducing condensation.

4.Hydrophilic Coatings

These coatings attract water, causing condensation to spread into a thin, clear layer rather than forming droplets. This technology is more common in exterior applications but can also be used on interior surfaces.

Applications and Benefits

Residential Homes

Bedrooms and Living Rooms: Large windows in these areas benefit from anti-condensation glass to maintain clear views and a comfortable indoor environment.

Bathrooms and Kitchens: High humidity areas where condensation is common can greatly benefit from anti-condensation glass to prevent moisture buildup.

Benefits

Improved Visibility: Keeps windows clear of fog and condensation, ensuring unobstructed views.

Reduced Mold and Mildew: By minimizing condensation, the risk of mold and mildew growth around windows is reduced.

Enhanced Comfort: Maintains a more consistent indoor temperature by reducing cold spots near windows.

Sunrooms and Conservatories

Applications

Sunrooms: Often have extensive glazing, making them prone to condensation. Anti-condensation glass helps maintain clear views and a comfortable environment.

Conservatories: Keeps the glass clear, ensuring optimal light transmission and a pleasant indoor climate.

Benefits:

Year-Round Usability: Prevents condensation, making sunrooms and conservatories comfortable and usable throughout the year.

Aesthetic Appeal: Maintains the visual clarity and attractiveness of these spaces.

Anti-condensation glass can contribute to the overall energy efficiency of a home by

1. Reducing Heating Costs:

– By preventing cold spots near windows, anti-condensation glass can help maintain a more consistent indoor temperature, reducing the need for additional heating.

2. Improving Insulation:

– Double or triple glazing with Low-E coatings improves the thermal insulation of windows, reducing heat loss and enhancing overall energy efficiency.

3. Lowering Maintenance:

– Reduces the need for frequent cleaning and maintenance associated with condensation and mold, saving time and resources.

The idea of heating glass is based on using energy-saving coatings made of metal oxides as heating elements. This option can be used to manufacture laminated glass and additionally as a safety glass panel. All the production processes for making heated glass panels are practically the same as the laminated glass process.

The idea of heating glass is based on using energy-saving coatings made of metal oxides as heating elements. This option can be used to manufacture laminated glass and additionally as a safety glass panel. All the production processes for making heated glass panels are practically the same as the laminated glass process.

The main difference is the power bus and temperature sensor, which control the heating temperature of the glass and prevent it from overheating. To minimize any damage, the conductive coating is always inside the laminated glass panels.

When a power source is connected to two electrodes located at each end of the pane, the glass coating converts the electrical energy into heat. The glass is heated to a temperature of 20-40°C (even if the outside temperature is below -30°C), creating a pleasant heat on its surface. For our heated glass, we use tempered glass which is much stronger than float glass. In some cases of failure or damage, the glass coating loses its integrity, activating an automatic fuse which cuts off the power to heat the glass.

Heated glass Features

1)Functionality:single or additional heating source,

full transparency,

insulation against heat losses,many opportunities to combine with other magic film products including the switchable privacy glass.

2)Durability:due to the tempering process and laminating,ecological materials,installation does not require any maintenance,

3)Sound insulation:reduction of noise in a room,

4)Innovative factors:additional sensor of an alarm system,high power,even heat distribution over all surface of a glass panel.

Transparent Electrical heated glass Application:

roof windows

facades

conservatories

glazing commercial buildings

performance and sports halls, swimming pools

hotels and restaurants

hospitals

museums

banks

- electricalldy heated glass dor display carbinet

- electrically heated glass dor food display

- Electrically heated glass

- electric heated glass

Aesthetics: Unimpeded transparency in all weather conditions; non-tinted appearance

Function: Prevents persistent fogging of outer pane

Usage Coating for use in double-glazing with an especially high Ug value.

| Technical Specification | |

| Max Size: | 3300 x 2400 mm |

| Thickness: | 3mm up to 300mm (multilayer laminated glass) |

| Color: | Wide range of different color – Sandplasting, Screenprinting |

| Shapes: | Any shapes – incl. holes and cut-outs |

| Glass-Type: | Float, tempered, coated, IGU, switchable |

| Power: | 12VDC – 380VAC |

| Anti | – 30℃ |

| Condensation: | – 100-300W/m2 |

| Add. | – 40 ℃ |

| Heater: | – 200-400W/m2 |

| Main | – 60 ℃ |

| Heater: | – 200-600W/m2 |

| Anti Snow and Ice: | – 80 ℃ |

| – 400-800W/m2 | |