Light effect PDLC Film Clarity

Lighting has a big effect on the clarity of glass. Even regular, monolithic glass will exhibit some haze when exposed to extreme lighting conditions. The haze effect is magnified, especially in direct sunlight.

1. Worse lighting conditions: Lights that are only on the outside of the conference room will cause an imbalance in light intensity. This will increase the haze.

2. Better lighting conditions: Lights on the outside of the conference room are higher in intensity than on the inside. This will result in a slight haze.

3. Best lighting conditions: Lights on the inside of the conference room and outside are evenly balanced in intensity and sufficiently diffused at appropriate distances.

4. Low haze in dark state (all lights off): No lights on the inside or outside of the conference room will result in little haze.

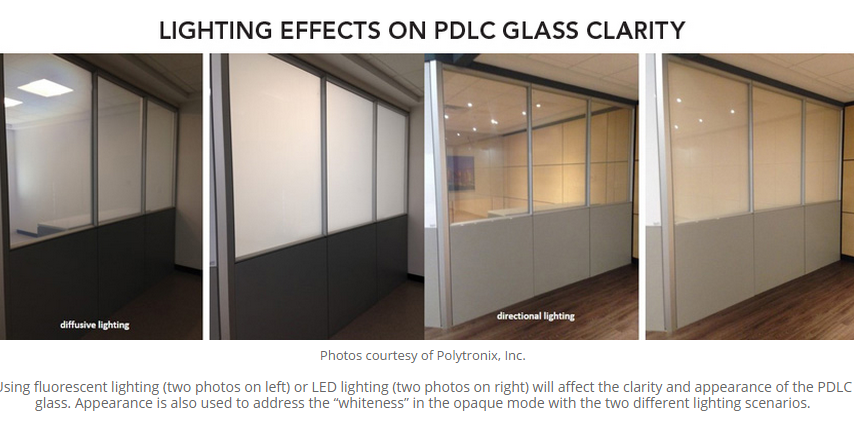

PDLC glass is also a light diffuser and the clarity can be impacted based on an imbalance of light intensities in the surroundings. The image below shows the difference in clarity between using fluorescent lighting (diffusive, large area, public) and LED lighting (directional, focused, small area, more intimate).

Additional Haze Factor Considerations

As discussed, PDLC glass contains liquid crystal (LC) material, therefore it inherently possesses some level of “haziness” and would not exhibit the same level of clarity as regular float glass. In addition, the inherent haziness is increased at wider viewing angles and with big disparities in light intensities (see diagram below). This phenomenon is normal because typical PDLC film/glass is a light diffuser and will change in haze at varying viewing angles as well as lighting conditions, as previously noted.

PDLC (Polymer Dispersed Liquid Crystal) film’s transparency and clarity depend heavily on light conditions (natural/artificial, angle, intensity).

1. PDLC Film Clarity in Different Light Conditions

| Light Condition | Effect on PDLC Film | Visual Outcome |

|---|---|---|

| Direct Sunlight (High Intensity) | Scattering increases due to LC droplet refraction | Slightly hazy/milky in ON (transparent) state |

| Low Light / Dim Room | Minimal scattering, best clarity | Near-perfect transparency in ON state |

| Backlighting (Behind Film) | Improves perceived clarity | Reduces haze, enhances transparency |

| Glare (Angle-Dependent Light) | Light diffusion varies with viewing angle | May appear uneven at extreme angles |

2. Factors Affecting PDLC Clarity Under Light

(1) Liquid Crystal (LC) Droplet Size

- Smaller droplets (1-5µm) → Less haze, better clarity.

- Larger droplets (>10µm) → More scattering, milky appearance.

(2) Polymer Matrix Quality

- Higher refractive index match between LC & polymer → Clearer film.

- Poor matching → Light scattering → Reduced transparency.

(3) Voltage & Frequency

- Optimal voltage (50-100V AC) ensures full LC alignment.

- Higher frequency (500Hz+) reduces flicker, improves stability.

(4) Ambient Light Temperature (CCT)

- Cool white light (6000K+) makes haze more noticeable.

- Warm white light (3000K-4000K) masks haze better.

How to Improve PDLC Clarity in Different Lighting

✔ For Bright Sunlight (Reducing Haze)

- Use anti-glare coatings (reduces surface reflections).

- Opt for high-grade PDLC films (e.g., >82% transmittance).

- Install behind tinted glass (reduces UV/IR interference).

✔ For Artificial Lighting (Indoor Use)

- Choose neutral/warm white LEDs (3000K-4500K).

- Avoid direct spotlighting (increases perceived haze).

- Use diffused lighting (softens LC scattering effects).

✔ For Projection Screens (Maximizing Clarity)

- Use rear-projection PDLC (light passes through film, not reflects).

- Ensure uniform backlighting (eliminates hot spots).

PDLC Film vs. Other Smart Glass Technologies (Clarity Comparison)

| Technology | Transparency (ON State) | Haze Level | Best Lighting Conditions |

|---|---|---|---|

| PDLC Film | 80-90% | Moderate (5-15%) | Diffused or backlit |

| Electrochromic Glass | 50-70% | Very Low (<5%) | All lighting |

| SPD (Suspended Particle) | 60-75% | High (20-30%) | Low-light preferred |

| Microblinds | 70-85% | Low (<10%) | Direct sunlight OK |

Common Issues & Fixes for PDLC Clarity

| Problem | Cause | Solution |

|---|---|---|

| Film looks hazy even when ON | Poor LC alignment, wrong voltage | Check power supply (50-100V AC) |

| Uneven transparency | Inconsistent coating or voltage | Test with multimeter, replace if defective |

| Yellowing over time | UV degradation | Use UV-stabilized PDLC or laminated glass |

| Glare/Reflections | No anti-glare treatment | Apply AR (anti-reflective) coating |

PDLC film clarity is best in diffused or backlit environments, while direct sunlight may increase haze. To optimize performance:

- Choose high-transmittance PDLC (>80%).

- Use proper voltage (50-100V AC).

- Control lighting temperature & angle.

- Consider anti-glare/UV-protective coatings.

For critical applications (medical displays, high-end smart windows), electrochromic glass may offer better clarity, but PDLC remains the best cost-effective switchable solution.