PDLC Liquid crystal has revolutionised transparency in modern materials. The unique property has led to its use in PDLC smart glass, switchable glazing and smart films. This revolutionary property comes from polymer dispersed liquid crystals, which embed liquid crystal droplets in a polymer matrix.

A Brief Overview of PDLC liquid Crystal

The unique substance Polymer Dispersed Liquid Crystal (PDLC) may change transparency. This intriguing property is based on liquid crystal droplets dispersion into a polymer matrix. Micro-size liquid crystal droplets in a polymer network from the PDLCs. The interaction between liquid crystal droplets and the poymer matrix is important to PDLCs.

Polymers are important in PDLC liquid crystals. The poymer matrix stabilises liquid crystal droplets, keeping them scattered. The alignment of these droplets varies when an electric field is applied, resulting in PDLC liquid crystal’s unique transparency change. We wil discuss how PDLC’s electrically changable nature makes it as a significant component in smart glass, switchable glazing and smart films.

Transparency Change Science

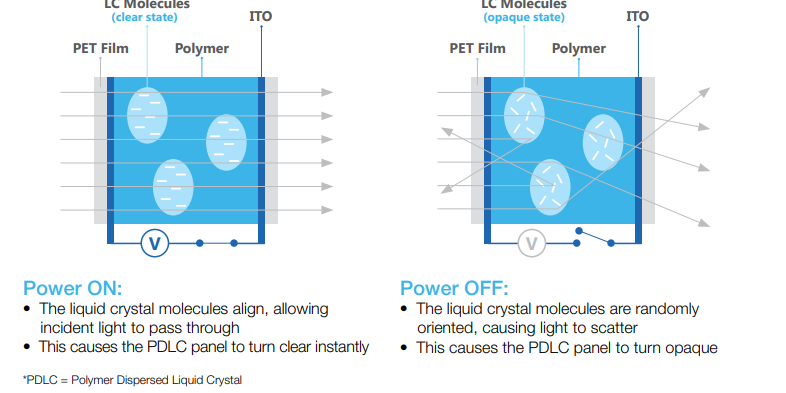

The unusual structure and composition of PDLC liquid crystal explain its transparency change. Without an electric field, polymer matrix liquid crystal droplets are randomly arranged. PDLC seems opaque due to this random orientation scattering light.

The game alters when an electric field hits the PDLC liquid crystal. The electric field causes liquid crystal droplets to align. Light passes through this alignment with minimal dispersion, making it transparent. The capacity to flip between opaque and transparent states defines PDLC liquid crystal.

Electrically adjustable PDLC is key to this transparency change. An electric field causes liquid crystal droplets to orient. PDLC liquid crystals are versatile for dynamic light control applications because they can modulate transparency by precisely controlling this electric field. It’s amazing how electricity and nanomaterials can transform.

PDLC Liquid Crystal Applications

This PDLC Film technology uses the transparency chang in PDLC liquid crystal to flip between clear and frosted glass at a flick. This makes it a great privacy control solution for offices, residences, and cars.

Switchable glazing using PDLC smart film. Thess windows later light transmission based on sunshine. Switchable glazing may control the quality of light and heat entering a building by using PDLC’s electrically changeable nature, which improves energy efficiency and comfort.

Finally, smart film applications use PDLC liquid crystals. The switchable transparency of PDLC liquid crystal use for smart film which is similar with smart glass. These smart films are flexible and be paste on existing glass surface to make them a cost-effective and versaatile privacy and light control option. The varitey of PDLC liquid crystal applications shows its potential to solve modern problems.

PDLC liquid crystal Manufacturing Insight

Formation of droplets and integration with a polymer matrix is a delicated and complex process for PDLC liquid crystal production.

Firstly, Liquid crystal droplets form. This is usually done through polymerization-induced phase separation. In this predure, liquid crystaals and monomers(Polymer building units) are mixed. Monomers form a polymer network when heated or illuminated. Droplets occur as liquid crystals are ejected from expanding polymer areaas during polymerization.

These liquid crystal droplets are integreated with the polymer matrix next. PDLC liquid crystal is formed when liquid crystal droplets embed in the polymer matrix during polymerzation. The optical properties of PDLC, including transparency, denpend on the froplet size and distribution in the polymer matrix.

The initial mixture composition, polymerization conditions, and cooling rate must be precisedly controlled throughout the process. PDLC liquid crystals have outstanding properties and numerous uses despite their complexity.