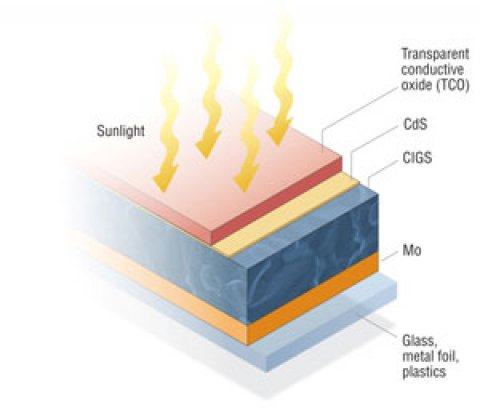

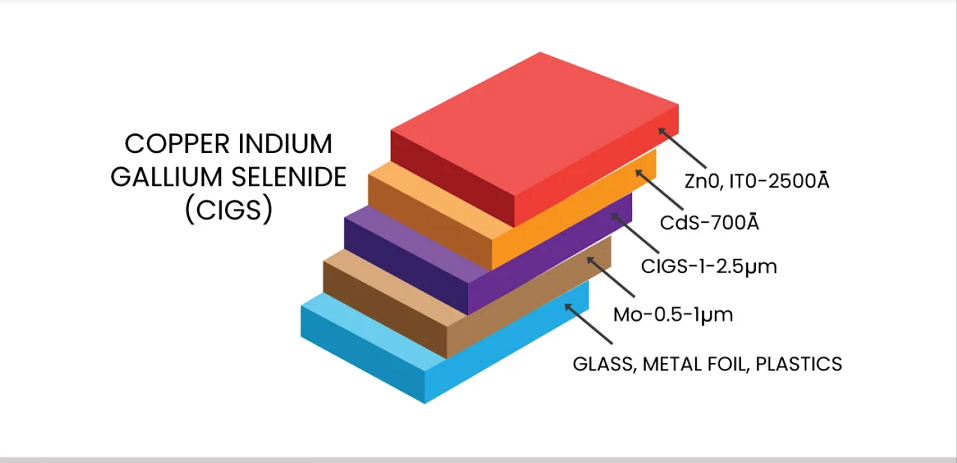

CIGS PV modules are manufactured using four vital layers:

Protective layer

Photovoltaic material

Conductive sheet

Substrate

(Layers of the CIGS thin-film solar panel – Source: Office of ENERGY EFFICIENCY & RENEWABLE ENERGY)

Each layer in the CIGS thin-film solar panel either plays a vital role in the solar energy conversion process or defines the application for the module, so each kinds of amterials are important.

In the manufacture of CIGS solar cells will use different materials, some include Direct-Current (DC) sputtering which is a variation of physical vapor deposition (PVD), Chemical Bath Depositions (CBD), Chemical Vapor Deposition (CVD), or co-evaporation processes.

The materials used in each layer of the manufacturing process for the CIGS solar cell are the following:

Frist :Protective layer

The protective layer names Transparent Conductive Oxide (TCO) layer. This layer protecting the CdS buffer from external damage installs in the cell through sputtering or CVD. The TCO layer works with Intrinsic Zinc Oxide (i-ZnO) placed over the CdS buffer, and then cover with an AZO compound layer made of Aluminum doped Zinc Oxide (Al: ZnO).

Second:Photovoltaic material or absorbing layer

The photovoltaic material is the heart of the CIGS solar cell. This is a p-n heterojunction manufactured by placing a p-type layer made from copper indium gallium selenide (CIGS) through co-evaporation and a p-type layer of Cadmium sulfide (CdS) deposited by CBD on top of the CIGS.

Third: Conductive sheet

The back contact or conductive sheet install directly on top of the substrate, before placing the photovoltaic material. Through by placing molybdenum (Mo) through DC sputtering, resulting in a highly reflective and conductive film working as the main contact for the cell.

Fourth :Substrate

The substrate is the backbone of the CIGS solar cell. flexibility and other properties of the cell will palace on the first layer where the rest of the materials defining . Varying on the desired properties for the module, substrate for CIGS solar cells can work with glass, a polymer names polyimide, or a metal foil of titanium, stainless steel, or a similar material.

(Essay on What Are CIGS Thin-Film Solar Panels? When to Use Them? (solarmagazine.com)

(Essay on What Are CIGS Thin-Film Solar Panels? When to Use Them? (solarmagazine.com)